Jul. 03, 2025

The price of capacitive touch screens is affected by many factors, including material cost, manufacturing process, functional requirements, market supply and demand, etc. The following is an analysis of the main factors:

1. Material cost

(1) Conductive layer material

- ITO (indium tin oxide): a traditional material with good light transmittance, but high cost and brittleness, which affects the yield rate.

- Nanosilver wire/metal grid: more flexible and suitable for curved screens, but low mass production yield rate and large price fluctuations.

- Graphene: an emerging material with strong conductivity, but not yet commercialized on a large scale and extremely high cost.

(2) Substrate material

- Glass substrate (such as GG, OGS): high cost, but good light transmittance and durability.

- PET film: used for flexible screens, low cost, but poor scratch resistance.

- Tempered glass (such as Corning Gorilla): 30%~50% more expensive than ordinary glass, but more resistant to drops.

(3) Touch IC and driver chip

- Imported chips (such as Synaptics, Cypress): stable performance, but high price.

- Domestic chips (such as Goodix Technology): high cost performance, but low market share in the high-end market.

2. Manufacturing process and yield rate

(1) Production process

- GFF (Glass-Film-Film): low cost, but poor light transmittance, mainly used in low-end devices.

- OGS (One Glass Solution): high integration, but easy to break when cut, yield rate is about 70%~80%, pushing up costs.

- In-Cell/On-Cell: integrated with the display, technically difficult, high initial cost, but more economical in the long run (such as iPhone uses In-Cell).

(2) Yield rate

- The defect rate in the production process (such as lamination bubbles, line breakage) directly affects the cost. For every 5% decrease in yield, the cost may increase by 10%~15%.

3. Size and resolution

(1) Screen size

- The larger the area, the more material is consumed, and the price increases nonlinearly (e.g., a 10-inch screen may be 3 times more expensive than a 5-inch screen).

- Special-shaped cutting (e.g., bangs screen, rounded corner screen) increases processing difficulty and cost.

(2) Resolution and touch accuracy

- High resolution (e.g., 4K) requires more precise electrode design, which increases the cost by 20%~30%.

- High reporting rate (e.g., 120Hz) requires high-performance chips, which are 10%~20% more expensive than 60Hz.

4. Functional requirements

(1) Number of touch points

- Single-point touch has the lowest cost, and 10-point touch increases the price by 20%~50%.

(2) Anti-interference ability

- Anti-electromagnetic interference (EMI) design (e.g., metal mesh shielding) increases the cost by 10%~15%.

(3) Special functions

- Waterproof and dustproof (IP67): requires sealing process, which increases the cost by 20%~30%.

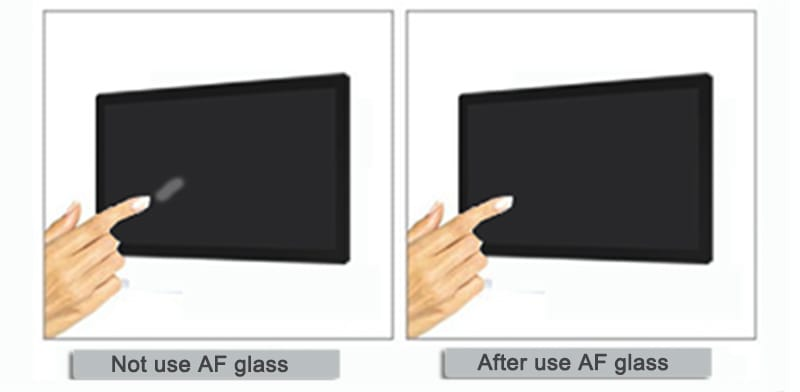

- Anti-fingerprint coating: Improves user experience, but increases costs by 5% to 10%.

- Flexible/foldable screen: The process is complex and the price is 2 to 3 times that of a rigid screen.

5. Market and supply chain factors

(1) Supply and demand relationship

- Cyclic fluctuations in the panel industry (e.g., price increases for touch ICs when there is a chip shortage).

- Emerging demands (e.g., large car screens, smart homes) push up short-term prices.

(2) Brand and customization

- The supply chain costs of high-end brands such as Apple and Samsung are 30% to 50% higher than those of white-label manufacturers.

- Customization requirements (e.g., special-shaped cutting, curved surface lamination) increase development costs.

6. Other factors

(1) Certification and compliance costs

- CE, FCC, RoHS and other certifications require additional testing fees (approximately 5% to 10% increase in costs).

(2) Transportation and tariffs

- Imported materials (e.g., Japanese ITO films) or exported finished products are subject to tariffs (e.g., tariffs imposed during the Sino-US trade war).

Summary

The price of capacitive touch screens is mainly determined by the following factors:

1. Materials (30% to 50%): ITO, nano silver wires, chips, etc.

2. Process (20%~40%): GFF, OGS, In-Cell, etc.

3. Function (10%~30%): multi-touch, waterproof, flexible, etc.

4. Market (10%~20%): supply and demand, brand, tariffs, etc.

Low-cost solution (such as GFF+domestic IC): about $5~$10 (small size).

High-end solution (such as In-Cell+imported chip): $50~$200 (large size/customization).

In the future, with the mass production of new materials such as nano silver wire and graphene, prices are expected to fall further, but high-end demand (such as folding screens) will still maintain a high premium.

+0086 755 21042870

+0086 755 2822 5493

Shenzhen Company: 5/F, Building 211, Tairan Science Park, Tairan 4th Road, Shatou Street, Futian District, Shenzhen(518040), China.

Dongguan Factory: 2/F, Building D, Fulin Industrial Park, Weixi Road, Dalingshan Town, Dongguan City(523831), Guangdong,China

NAVIGATION

REQUEST A QUOTE