Jul. 04, 2025

The price of capacitive touch screens is affected by a variety of factors, including material cost, structural size, functional demand, market supply and demand, etc.

The following is an analysis of the main factors:

1. Material Cost

(1) Conductive layer material

-ITO (indium tin oxide): traditional material, good light transmittance

-Nanosilver wire/metal grid: touch screens are widely used

(2) Sensor substrate material

-Glass substrate

-PET film

(3) Touch IC and driver chip

-Imported chips: EETI, ILITEK, SIS.

- Domestic chips: Chuyu, Hanruiwei.

2. Structure and yield rate

(1) Structure

-GFF (Glass-Film-Film)

G+G (One Glass Solution)

(2) Product rate

- Currently, it can basically reach more than 95%

3. Size and resolution

(1) Screen size

-The larger the area, the more material consumption, and the nonlinear price increase (such as a 10-inch screen may be 3 times more expensive than a 5-inch).

-Special cutting (such as notch screens, rounded corner screens) increases processing difficulty and cost.

(2) Resolution and touch accuracy

- Depending on the resolution of the control chip, it can reach up to 16383*16383.

- Single-report rate can reach 200Hz, and multi-point can reach above 100Hz. Depends on whether the host can handle the high quotation rate.

4. Functional Requirements

(1) Number of touch points

- Single touch is the lowest cost, with the price of 10-point touch increased by 20% to 50%.

(2) Anti-interference ability

- Anti-electromagnetic interference (EMI) design (such as metal grid shielding) increases the cost by 10%~15%.

(3) Special functions

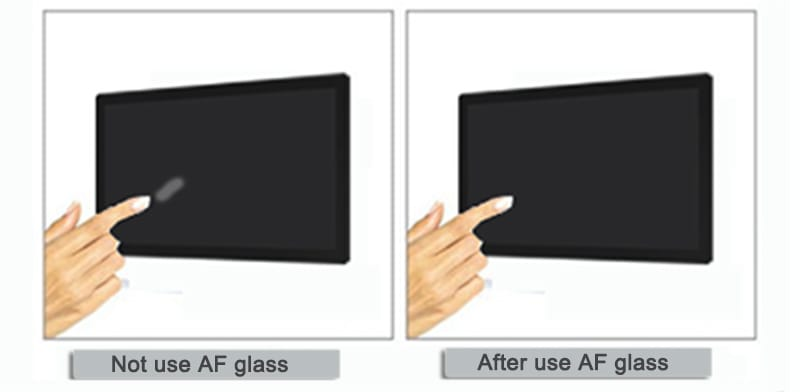

-AG

-AR

-AF

5. Market and supply chain factors

(1) Supply and demand relationship

-Panel industry fluctuates periodically (such as touch IC price increase when chips are short).

-Emerging demand (such as large-vehicle screens and smart homes) pushes up short-term prices.

(2) Brand and customization

-The supply chain costs of high-end brands such as Apple and Samsung are 30% to 50% higher than those of white-label manufacturers.

- Customized requirements (such as special-shaped cutting, surface fitting) increase development costs.

6. Other factors

(1) Certification and compliance costs

- CE, FCC, RoHS and other certifications require additional testing costs (about 5%~10% increase in cost).

(2) Transportation and customs duties

- Imported materials (such as Japanese ITO membrane) or exported finished products are affected by tariffs (such as tariffs imposed by the Sino-US trade war).

Summarize

The price of capacitive touch screens is mainly determined by the following factors:

1. Materials (30%~50%): ITO, PET film, etc.

2. Structure and size (20%~40%): G+G, GFF and size, etc.

3. Functions (10%~30%): AG, AR, AF, etc.

4. Market (10%~20%): supply and demand, brand, tariffs, etc.

- Low-price or high-price solution: mainly depends on the cost of the control card and the selected process

If you want to know about touch screen related issues or want to design different sizes and shapes, please feel free to contact us.

+0086 755 21042870

+0086 755 2822 5493

Shenzhen Company: 5/F, Building 211, Tairan Science Park, Tairan 4th Road, Shatou Street, Futian District, Shenzhen(518040), China.

Dongguan Factory: 2/F, Building D, Fulin Industrial Park, Weixi Road, Dalingshan Town, Dongguan City(523831), Guangdong,China

NAVIGATION

REQUEST A QUOTE