Jul. 16, 2025

01. The role and challenges of glass cover

Cover glass, as the outermost protective material of the touch screen, is mainly divided into two categories: soda-lime glass and high-aluminum glass. The cover glass

made by special technology not only has multiple functions such as impact resistance, scratch resistance, oil resistance, anti-fingerprint and enhanced lighttransmittance,

but also faces many challenges due to direct contactwith the outside world. Therefore, key attributes such as high hardness, pressure resistance and scratch resistance

have become important standards for measuring the quality of cover plates.

02. Three major surface treatment technologies

The surface treatment of glass cover plates mainly covers three categories: AG, AR, and AF. Next, we will explore the different effects brought by these three surface

treatment technologies.

▍ AG glass application and identification

Through chemical etching or spraying technology, the originally smooth glass surface is transformed into a diffuse surface, thereby adjusting its reflective properties

and producing a matte visual effect. This treatment allows external light to form diffuse reflection on the glass, effectively reducing the glaring light reflection and

providing a more comfortable visual experience.

AG glass is widely used in outdoor and strong light display occasions, such as advertising screens, ATM machines, POS cash registers, medical displays, e-book readers,

and subway ticket machines. According to the use environment and budget considerations, indoor glass can be sprayed with anti-glare coating, while outdoor glass is

recommended to use chemical etching to ensure the durability of the AG effect.

The method of identifying AG glass is very simple: observe the front of the glass under fluorescent light. If the light source is scattered, it means that the glass has been

AG treated; if the light source is clearly visible, it means that the glass has not been AG treated.

▍ Application and identification of AR glass

The reflectivity of glass treated with optical coating is significantly reduced, while the transmittance is greatly improved. The transmittance of this glass can reach more

than 99%, while the reflectivity is reduced to less than 1%. Such improvements make the displayed content clearer and more visible, providing viewers with a more

comfortable and clear visual experience.

AR glass is widely used in many fields, including glass greenhouses, high-definition displays, photo frames, mobile phone and camera lenses, front and rear windshields

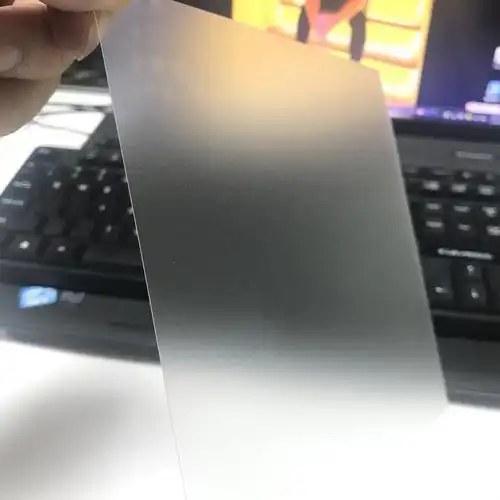

of cars, and solar photovoltaic industries. To identify AR glass, you can compare a piece of ordinary glass with a piece of AR glass. On a computer or other display screen,

the clarity of AR coated glass will be significantly better than that of ordinary glass.

▍ Application and identification of AF glass

AF coating technology, inspired by the principle of lotus leaves, covers a layer of nanochemical materials on the surface of the glass, giving it excellent hydrophobic,

oil-proof and anti-fingerprint properties. This glass is easy to clean, whether it is dirt, fingerprints or oil stains, it can be easily wiped off, keeping the surface smooth

like a mirror and smooth to the touch.

Anti-fingerprint glass is widely used in display glass cover plates of various touch screens, and its AF coating is only applied to the front of the glass. To identify AF glass,

you can simply drop a drop of water or test it with an oil pen. Water drops will form water beads on the AF surface and can roll freely, while the non-AF surface will

appear like a water pool; similarly, if you draw lines on the AF surface with an oil pen, you will find that the lines cannot be seen.

SHENZHEN GDT CLOUD BRAIN TECHNOLOGY CO., LTD (GDT) has been engaged in the manufacturing and production of the touch screen industry for many years

and is proficient in various processes of glass cover plates. Strict quality control and trust from old customers. In the future, we will continue to forge ahead and create

brilliance. If you have anything you want to know in the touch industry, please feel free to consult us.

+0086 755 21042870

+0086 755 2822 5493

Shenzhen Company: 5/F, Building 211, Tairan Science Park, Tairan 4th Road, Shatou Street, Futian District, Shenzhen(518040), China.

Dongguan Factory: 2/F, Building D, Fulin Industrial Park, Weixi Road, Dalingshan Town, Dongguan City(523831), Guangdong,China

NAVIGATION

REQUEST A QUOTE